What it does

Zero Warm-up Source optical architecture improves optical light source performance, measurement accuracy & work practices.

It is unique in the industry, and only adds a modest extra cost for performance-critical users.

Note: This feature is only applicable to KI2300 (Loss Test Set), KI2400 (Light Source) and KI23400 (2-way Loss Test Set) series.

User benefits

- Improved source stability during emitter warm up. Most users will see effectively zero source drift due to warm up.

- Improved source stability over temperature. Particularly useful for long term monitoring.

- Improved source stability under varying ORL conditions.

- Highly stable eLED SM source option for high stability loss testing or CD testing

Explanation

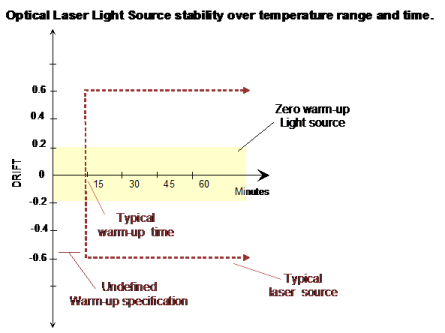

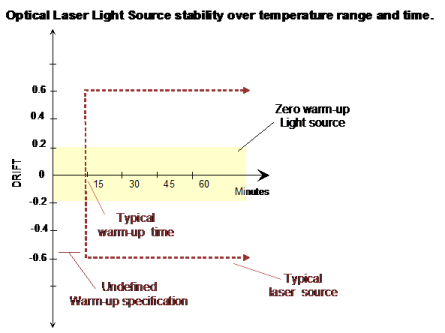

Laser / LED thermal power stability is critical for source stability. The performance is to be found in data sheets for laser devices under something like "tracking error". A"typical" specification is between ±0.5 - ±1 dB over temperature range of say -20 to 50°C. A batch of lasers will show quite different individual characteristics, so sample testing the performance of one instrument may not be representative: it's easy to cherry-pick a great sample.

If an instrument is used in a very stable temperature, then this issue largely shows up as "warm up" drift. However if its used in a typical instillation environment, then output power can drift substantially, and this performance will depend on the particular s/n of instrument used.

We have found that for lower specification Kingfisher sources, the thermal stability specification is ±0.6 dB over a temperature range of 70 °C. Many competitor sources wouldn't achieve this.

For example, a user takes our source from an air conditioned car at say 20 °C, and gets out into either the desert heat at say 40 °C, or a cold day at say 0 °C. The change of 20 °C can easily induce an instability of say 20/70 x 0.6 dB = ±0.17 dB. while the instrument temperature changes over say 20 minutes.

Even in a laboratory environment, if the sun swings round onto a bench with the instrument, or the air conditioner turns off at the end of the day, then sensitive experiments can vary significantly.

The unique Kingfisher Zero Warm Up Source has a much tighter stability specification of ±0.2 dB over temperature. The equivalent instability in the example given, would be 20/70 x 0.2 dB = ±0.06 dB.

Warm up stability

Warm up stability is essentially a sub-set of stability over temperature. In other words, after turn-on, the laser device warms up by a few degrees over 10 - 20 minutes. This can vary substantially between identical p/n instruments.

Assuming a laser device tracking error of say 0.6 dB, and a laser device warm up of say 5 °C, then the warm up drift would be 5/70 x 0.6 dB = ±0.04 dB. However for a Zero Warm-up device, it will be about 0.014 dB.

The irritating thing about this warm-up, is that it happens every time the particular laser is turned on, eg any time the source wavelength is changed, and not just at instrument turn-on. This can seriously affect productivity of users testing at multiple wavelengths. Autotest helps significantly here, since all lasers are kept on continuously at eg 50% duty cycle.

The majority of instrument manufacturers dodge the issue by only specifying stability "after warm-up", and with a very tight ambient temperature variation, effectively in an environmental chamber.

The Zero Warm up Source architecture reduces warm up drift to a negligible level.

Long / Short term stability

This often quoted light source specification is really just another way of looking at thermal stability. It is usually measured and specified in such ideal circumstances (eg in an environmental chamber, after warm up) as to not usefully represent what a user will achieve "on the job". We quote this on our data sheets to allow comparison with other products, however it's not a very dependable specification in practice.

Optical return loss stability

The power output of all laser sources (that don't incorporate an isolator) is affected by return loss. Our experiments indicate a dependence large enough to affect precision loss testing. The real problem is that as the source is moved between test items with differing ORL, the source power varies a bit, and so the loss measurements vary a bit. The user is usually unaware that this is happening.

Effect on work practices & test procedures

Practical Work practices and test procedures have to take into account the reasonable worst-case performance of both people and equipment. Therefore, equipment specification limits are more important than "average" performance. In this situation, the tight specifications of the Zero Warm Up sources are a clear winner when it comes to test uncertainty.

Obviously, if warm-up delays can be avoided, then much more work can be done in the same time, with greater confidence.